Have you ever been in a position where you couldn’t drill straight because the angle was too restrictive? Or maybe you need a tool that would make accessing those hard-to-reach places a little easier? Enter the Winkelbohrspindel. This brilliant gadget will likely be the answer to all your drilling problems. Thanks to its special shape and the many possibilities to use it, it now has a great appeal to DIY’ers and professionals.

In this full article, you will get to know everything about Winkelbohrspindel. Types of Origin, Types, Applications and Major Features We will tell you everything. Whether you’re an old hand at the tool or a first-time user, getting to know this unique tool can take your projects to the next level. Let’s go and discover the world of Winkelbohrspindels!

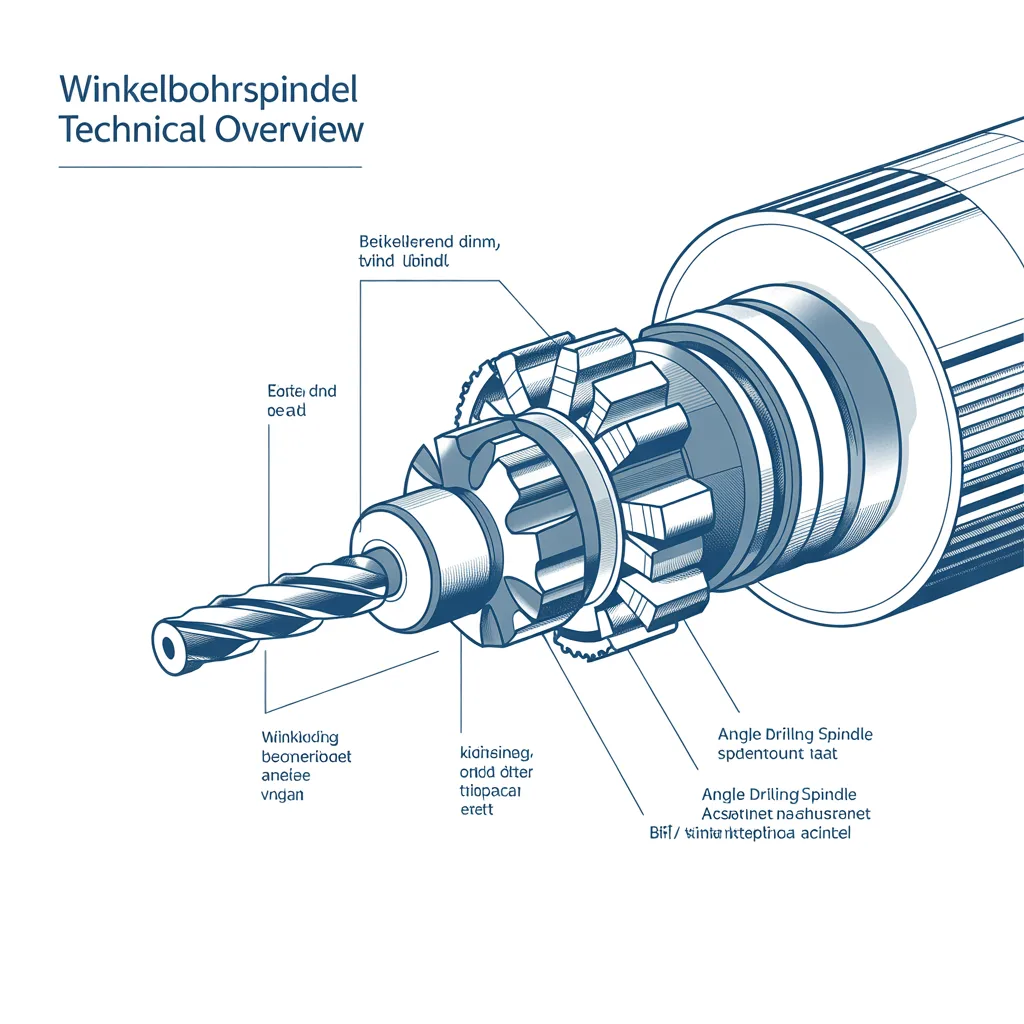

What is a Winkelbohrspindel?

A Winkelbohrspindel, also known as an angular drilling spindle, is a special tool for drilling with high precision at difficult angles. This one of a kind tool gives you the ability to get into those tight spaces a normal drill won’t fit or can’t get close enough.

The construction contains a rotary shaft with the axis of rotation is adjustable to multiple angles at different working conditions. Its main purpose is creating angled holes in wood, metal and other materials at high speed and without sacrificing accuracy.

Winkelbohrspindel are used in cabinet and furniture work where precision is needed for intricate patterns. They streamline your workflow by reducing the number of times you have to move a workpiece or switch tools.

This revolutionary instrument is a must-have for woodworkers and metalworkers who need their tools to be as versatile as their projects. For handling sophisticated works with ease, the Winkelbohrspindel is an essential tool to carry in any toolkit.

The Origin of Winkelbohrspindel: Where Did It Come From?

The Winkelbohrspindel (drilling spindle at an angle) arose in machining technology early history. It was introduced as a means of increasing the accuracy of work done on wood and metal.

This innovative handy tool was born in Germany where drill engineers were trying to figure out how to get drills into small spaces. The angle design provides access to the corner or wall without losing power or precision.

As different equipment was needed, so it was adapted until it was used all over Europe. Artisans enjoyed how it made them more efficient while also putting less stress on their hands when working with fine detail.

Along with technology advancing, the Winkelbohrspindel advanced. Today™s products utilize optimum in high speed and are made from advanced materials ensuring long term durability and performance.

Its history is a story of necessity and resourcefulness – two qualities that have come to define the very heart of our industry.

Types of Winkelbohrspindel

Winkelbohrspindel Kennt man verschiedene Arten, die alle für unterschiedliche Anforderungen gedacht sind. Die gebräuchlichste Ausführung ist der standardmäßige Winkelfalzfräser, der sich ideal für allgemeine Bohranwendungen eignet.

Es gibt noch eine andere Sorte, die High Speed Winkelbohrspindel. This model is best for speedy work, suitable for use in a production workshop which the efficiency is importance.

There’s even a micro-angle spindle for precision work. It is now possible to drill holes micro-holes with extremely high accuracy even with a small size .

There are also special models dedicated for specific uses, such as woodturning or metalworking. These are special spindles designed and engineered to meet particular needs and are often of rugged construction.

TheyWon’tWinLoseInWhatTheyThinkSome advanced Winkelbohrspindels include digital controls and automation functions. These advanced tools add usability enhancements without sacrificing repeatable results on multiple projects. Each variant in a range has its own role or application to serve in the world of trade and engineering.

Winkelbohrspindel vs Other Tools: Key Differences

If you compare the Winkelbohrspindel with conventional drilling tools, the differences are quite obvious. The Winkelbohrspindel is tailored specifically for angled holes and isn its a horizontal or vertical plane like standard drilling tools.

Another important difference lies in accuracy. The accuracy of the Winkelbohrspindel enables you to achieve better end results if you are making complex designs or working in confined areas, so it’s a excellent option for specialized areas where detail is need.

Also remarkable is how versatile the Winkelbohrspindel is. Although a number of tools exist that are specifically designed for a certain type of materials or application, this tool works excellently on multiple projects and surfaces.

Ease of use is an important aspect of its popularity. Its ergonomic design provides for comfortable handling while using the product for long periods minimizing hand fatigue unlike bulky products you find today.

Key Features of Winkelbohrspindel

The Winkelbohrspindel is characterised by accuracy and flexibility. Thanks to its oblique shape, you can reliably work even in very narrow places where the use of other tools is excluded.

Another major feature is the solid structure. Built with premium-grade materials, it will last and perform for a long time, even in harsh environments. This durability has made it the go-to choice for professionals who need reliable equipment.

ease of Use is also a feature to be mentioned here. Two or three setting options are adjustable for most models of this tool and this feature makes the tool increasingly versatile even more different projects.

In addition, compatibility is critical. The Winkelbohrspindel can be used with a vast array of machines and tools, giving you versatile solutions for your workshop needs.

Ergonomically designed Many Winkelbohrspindels are designed to be ergonomic. They encourage you to remain comfortable when working with them for long periods, diminishing tiredness and helping you be more productive when you’re working on complex projects.

Applications of Winkelbohrspindel

Winkelbohrspindel is suitable for many applications in different industries, Whether in the industry or in the workshop. In woodwork, it is used to make angled holes for furniture joints or decorative work.

The automotive industry depends on Winkelbohrspindel for drilling accurate holes in hard to reach places. This allows for a better fit between parts, which makes everything run more smoothly.

For metalworking, this instrument is indispensable for generating repeatable results over complicated shapes. So engineers have the flexibility to address unique, one-off challenges without sacrificing quality.

Electronics products are also capable of being processed by a Winkelbohrspindel with accuracy. It is often used to drill circuit boards, where precision is very important.

Building work is no doubt the same, and you’ll have applications there for hanging paintings and the like, with an adjustable angle to the drill; with the drill this way you can then also saw. With the versatile nature of Winkelbohrspindel, you too, can have your desired result in professional workmanship.

Maintenance and Longevity

The correct maintenance is essential if you want the Winkelbohrspindel to last. Cleaning prevents the build up of dirt that could affect performance. A simple cleaning after use does wonders.

Regularly checking components allows for wear and tear to be identified early. Watch for damage or unusual noises during operation — these may be signos of internal problems.

Lubrication is a big factor too. The right lubricant reduces the friction and heat which in turn extends the life of the tool.

The dry storage of your Winkelbohrspindel also helps its sustainability. Moisture can cause rust and corrosion with time.

With these maintenance suggestions, your Winkelbohrspindel will keep running like new, allowing you to power through a variety of jobs with confidence for many more years to come.

Final thought

Knowing how the Winkelbohrspindel works in precision engineering is the key to many doors. This thing can do so much that it should be in the toolkit of every pro and hobbyist.

This device’s flexibility also enables intricate patterns and demanding projects, which further add to its effectiveness within the different industries. There isn’t an application that shows off its capabilities better than that one, whether it’s woodworking or metalworking.

As tools evolve, so does the potential of tools like the Winkelbohrspindel. Further innovations will likely broaden the scope of applications, and it will become an indispensable tool for the modern workshop.

Learning about this tool may be a time investment you will get better skills out of your work and better results. Such advances might lead to more efficient processes and more creative solutions in your projects.

Conclusion

The Winkelbohrspindel is a fantastic device that enables you to shine through in many areas. It is the perfect professional and hobby drillers tool.

Knowing all of its benefits can allow the user to be more productive for their work. Whether you lean towards versatility or precision, this tool collects some features for each need.

Looking at other solutions can also help you understand your needs. The comparison of products allows us to learn more about what is available in the market today.

Anyone thinking about getting a Winkelbohrspindel for their toolbox in the first place would be wise to take a look at their own projects and jobs first. That knowledge when to use and how to use such machinery will make every effort worth it each time.

Chatting with other hobbyists or pros can also enhance your awareness of what can be done with this particular tool in many industries.

FAQs

What is a Winkelbohrspindel used for?

The Winkelbohrspindel (angular drilling spindle) is mainly used in mechanical processing for drilling holes at different angles. It is especially useful when machining materials that must be approached quickly and efficiently.

How does a Winkelbohrspindel differ from a regular drill?

The principal difference is in the construction. Conventional drills work on the vertical axis, the Winkelbohrspindel is for drilling at an angle. This makes it perfect for jobs where headroom is at a premium or where holes must be drilled in a certain direction.

Can I use a Winkelbohrspindel on different materials?

Yes! An Winkelbohrspindel can be used for wood, metal and plastics. The type of bit you use will depend on the material you are drilling.

How do I maintain my Winkelbohrspindel?

Routine maintenance is also to wipe down the spindle after use to avoid accumulation of dust and debris. Make sure that all moving parts are properly lubricated to maximize life and performance.

Is it easy to find replacement parts for a Winkelbohrspindel?

Spare parts are usually available from the tooling manufacturers or specialist suppliers. Before buying any parts, always make sure they are compatible.